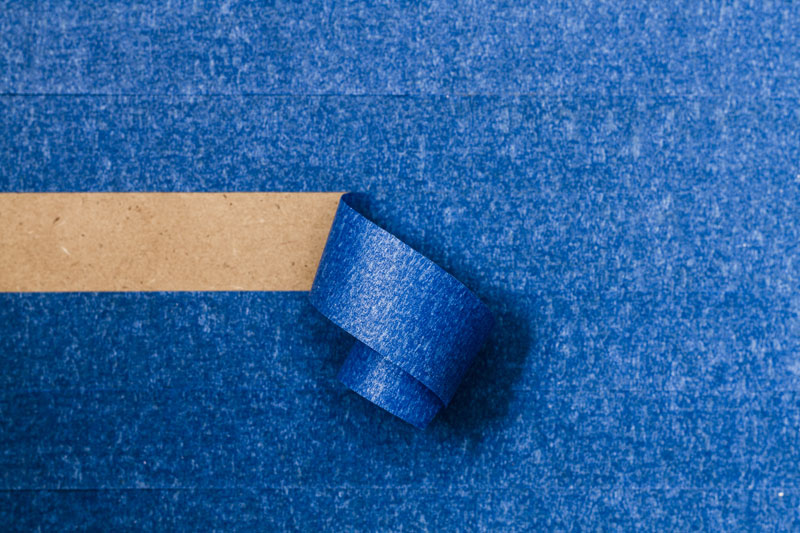

Weather Stripping Single Sided Self Adhesive Foam Seal Strip High Density Foam Weatherstrip Tape

✅ Weather Stripping Single Sided Self Adhesive EVA Foam Tape Seal Strip High-tack adhesive ensures strong bonding on uneven surfaces and diverse materials. ✅ Weather Stripping Single Sided Self Adhesive Foam Seal Strip Pressure-sensitive design allows instant adhesion without curing time or special tools. ✅High Density Foam Weatherstrip Tape Seal Strip Thermal-resistant variant withstands extreme

- ODM/OEM

- China

- 5-20days

- 50tons-100tons

Details

Weather Stripping Single Sided Self Adhesive Foam Seal Strip Products Information

Foam tape is an adhesive tape made of foam as the base material, with adhesive coated on one or both sides. It integrates multiple functions such as cushioning, sealing, fixing, and shockproofing, and is widely used in electronics, construction, automotive, and household fields.

Product name: | Weather Stripping Single Sided Self Adhesive EVA Foam Tape Seal Strip |

Brand: | LOP |

Size: | CUSTOMIZE |

Thickness: | CUSTOMIZE |

Deliivery: | 7DAYS |

Payment: | 30%Deposit 70%Final payment |

Weather Stripping Single Sided Self Adhesive EVA Foam Tape Seal Strip Structure

The core is foam substrate, with common materials including polyethylene (PE), polyurethane (PU), ethylene-vinyl acetate copolymer (EVA), etc., which are elastic, compression-resistant, and aging-resistant. The adhesive coated on the surface is mostly acrylate, rubber, or silicone adhesive, ensuring strong bonding with different materials (metal, plastic, glass, etc.).

Single Sided Self Adhesive Foam Seal Strip Key Features

Cushioning and shockproofing: The porous structure of foam can absorb impact and vibration, protecting precision components (e.g., electronic devices, auto parts).

Sealing and waterproofing: It can fill gaps, block moisture, dust, and noise, suitable for door/window and pipeline sealing.

Strong adaptability: Wide temperature resistance range (usually -40℃ to 120℃), resistant to ultraviolet rays and chemical corrosion, adapting to complex environments.

Easy construction: No drilling or welding required; it can be fixed by direct pasting, simplifying the installation process.

The thickness of EVA Foam Tape is a critical parameter that significantly influences its performance, directly affecting its cushioning ability, gap-filling efficiency, bonding strength, and suitability for specific applications. Here’s a detailed breakdown of how thickness impacts its properties:

1. Cushioning and Shock Absorption

Thicker Tapes (typically ≥3mm): The more voluminous foam core in thicker tapes provides greater compressibility and deformation space. This allows them to effectively absorb impacts, vibrations, and sudden shocks—making them ideal for protecting fragile items (e.g., glass, electronics) during transportation or securing components in machinery where vibration resistance is critical.

Thinner Tapes (≤1mm): With a denser, less flexible foam structure, thinner tapes offer limited cushioning. They are better suited for applications where shock absorption is secondary, such as lightweight mounting or surface sealing with minimal impact exposure.

2. Gap-Filling Capability

Thicker Tapes: Their increased bulk enables them to fill larger or irregular gaps between uneven surfaces (e.g., between metal panels, wall fixtures, or machinery parts). When compressed, they conform to surface imperfections, creating a tight seal that prevents moisture, dust, or air leakage.

Thinner Tapes: Designed for narrow, uniform gaps. They excel at bonding smooth, closely aligned surfaces but may fail to seal or stabilize joints with significant unevenness, leading to poor adhesion or gaps over time.

3. Bonding Strength and Longevity

Thicker Tapes: The foam core’s compressibility distributes pressure more evenly across the bonded area, enhancing contact with irregular surfaces and improving long-term adhesion. However, excessive thickness can reduce immediate "tack" (initial stickiness) if not properly compressed, requiring more pressure during application to activate the adhesive fully.

Thinner Tapes: Offer stronger immediate adhesion on smooth surfaces due to greater contact between the adhesive layer and the substrate. They are less reliant on compression for bonding but may struggle to maintain strength on rough or curved surfaces where gap-filling is needed.

4. Flexibility and Conformability

Thicker Tapes: While bulkier, high-quality thick tapes (e.g., polyurethane or EVA-based) retain flexibility, allowing them to conform to curved surfaces (e.g., automotive trim or rounded edges). However, overly thick rigid foams may crack or peel on highly contoured surfaces.

Thinner Tapes: Excel at conforming to fine details or tight curves due to their low profile, making them suitable for precision applications like electronics assembly or intricate craftwork.

5. Environmental Resistance

Thicker Tapes: In outdoor or harsh environments, thicker foam cores (especially closed-cell types) provide better insulation against temperature extremes, moisture, and UV radiation. Their structure creates a more robust barrier, extending the tape’s lifespan in exposed settings (e.g., outdoor signage or construction seals).

Thinner Tapes: Offer limited insulation but may be preferred for indoor, low-exposure uses where a discreet profile is prioritized over long-term environmental resilience.

In summary, thicker EVA Foam Tape prioritize cushioning, gap-filling, and durability, while thinner ones excel at precision bonding, flexibility, and low-profile applications. Choosing the right thickness depends on the specific demands of the surface, environment, and functional requirements.

Weather Stripping Foam Seal Strip Products Equipments

1. Production Capacity & Scale 24/7 operations with 500,000+ rolls/day output (standard 48mm×50y).high-volume production for industrial, masking, and double-sided tapes.

2. Core Technologies & Equipment German servo-driven extruders process BOPP/PVC/PET substrates at 150m/min.Laser-guided slitting/rewinding systems with ±0.1mm width tolerance.

3. Precision & Quality Control coating thickness accuracy ±0.002mm (Swiss precision gauges).CCD vision inspection and closed-loop tension control ensure <0.3% defect rate.

4. Automation & Smart Systems AGV robots and intelligent palletizing for end-to-end material handling.real-time MES monitoring with <0.5s anomaly response.Honeywell sensors for process optimization.

5. Sustainability & Compliance RTO emission treatment units and ISO 14001 certification.Energy-efficient,closed-loop production cycles.

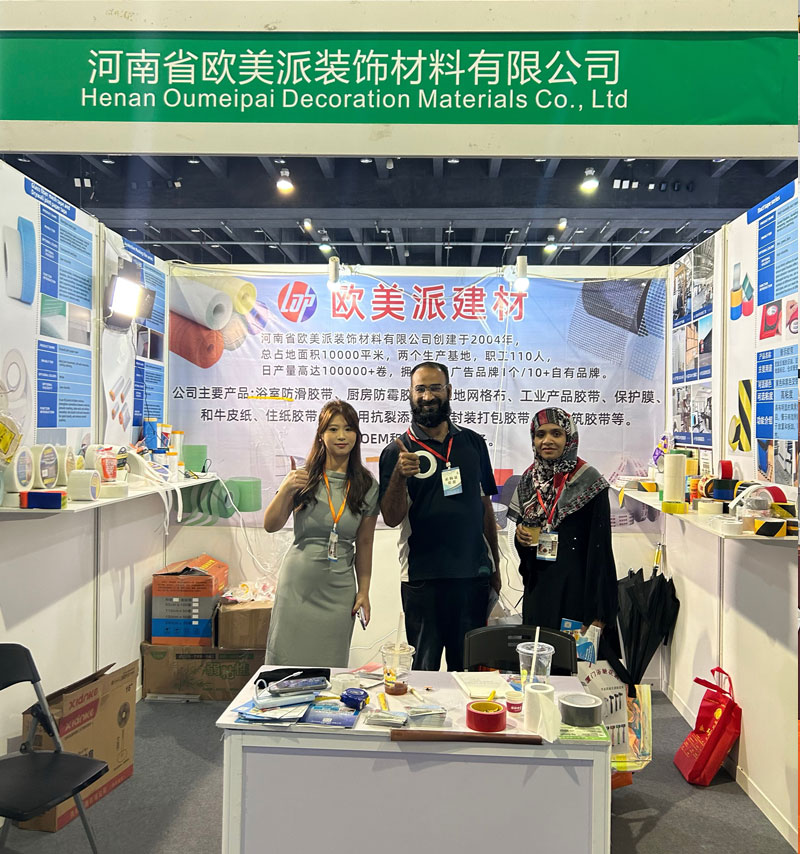

Oumei Pai Decoration Materials Tape Factory

Our Team

Our Exhibition

Product Application Scope

Henan Oumei Pai Decoration Materials Co., Ltd. main products include construction site mesh cloth, industrial product tape, protective film, paper tape, anti cracking additives for construction, packaging tape, kraft paper, housing construction tape, etc. Provide OEM and ODM customization services. The products are mainly sold domestically in the major building materials and auxiliary materials markets in China, and exported to regions such as Europe, America, and the Middle East.

Weather Stripping EVA Foam Tape Packing and Delivery

ü Our packaging and logistics systems combine automated cartoning, robotic palletizing (1,200 rolls/minute), and smart inventory tracking to ensure rapid, error-free order processing.

ü Climate-controlled warehouses with RFID technology safeguard product quality across 50,000+ pallet spaces.

ü Partnering with global logistics leaders, we offer flexible air/sea/land freight options with 98.5% on-time delivery, enhanced by AI route optimization.

ü Sustainable FSC-certified recyclable packaging and ISO 14001-aligned processes minimize environmental impact, delivering efficiency from production to worldwide destinations.

FAQ

Q:Are you factory or trading conpany

A:We are real factory located in zhengzhou city Henan province,anytime can visit our factory

Q:What product is your factory supplying

A:All kinds of tape we can make,masking,opp,double side,fiberglass...

Q: What payment methods are accepted?

A: TT, L/C, 30%-50% deposit for initial orders.

Q: What is the lead time?

A: Standard orders: 7-15 days; expedited orders: as fast as 5 days (subject to capacity).