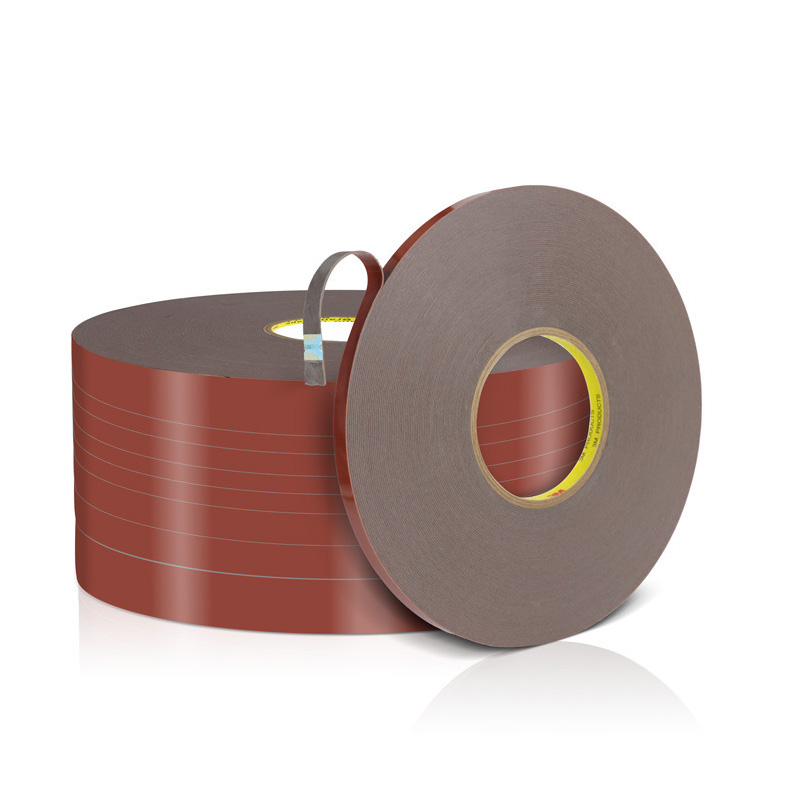

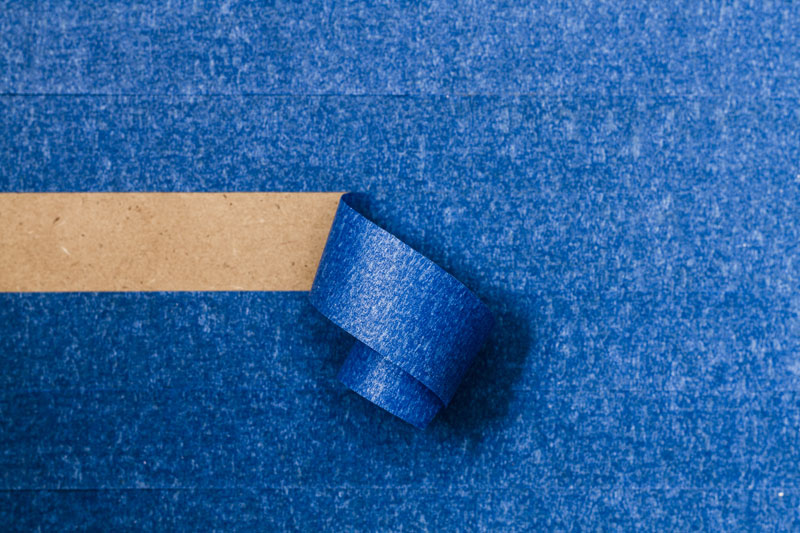

Heavy Duty Mounting Waterproof Strong Adhesive Acrylic Foam Tape

✅ Heavy Duty Waterproof Adhesive Acrylic Foam Tape High-tack adhesive ensures strong bonding on uneven surfaces and diverse materials. ✅Heavy Duty Waterproof Adhesive Acrylic Foam Tape Pressure-sensitive design allows instant adhesion without curing time or special tools. ✅Heavy Duty Waterproof Adhesive Acrylic Foam Tape Thermal-resistant variant withstands extreme

- LOP

- CHINA

- 7-10days

- 100000pcs/days

Details

Heavy Duty Mounting Waterproof Strong Adhesive Acrylic Foam Tape Products Information

Acrylic Foam Tape is a pressure-sensitive adhesive (PSA) product consisting of a foam core (e.g., polyethylene/PE, ethylene-vinyl acetate/EVA, or polyurethane/PU) coated with adhesive layers (acrylic or rubber-based) on one or both sides. It combines cushioning, sealing, vibration damping, and gap-filling properties, making it ideal for uneven surfaces and demanding applications.

Product name: | Heavy Duty Waterproof Adhesive Acrylic Foam Tape |

Brand: | LOP |

Size: | CUSTOMIZE |

Thickness: | CUSTOMIZE |

Deliivery: | 7DAYS |

Payment: | 30%Deposit 70%Final payment |

Acrylic Foam Tape Key Features

Cushioning and shockproofing: The porous structure of foam can absorb impact and vibration, protecting precision components (e.g., electronic devices, auto parts).

Sealing and waterproofing: It can fill gaps, block moisture, dust, and noise, suitable for door/window and pipeline sealing.

Strong adaptability: Wide temperature resistance range (usually -40℃ to 120℃), resistant to ultraviolet rays and chemical corrosion, adapting to complex environments.

Easy construction: No drilling or welding required; it can be fixed by direct pasting, simplifying the installation process.

Can the thickness of Acrylic Foam Tape be customized to meet specific requirements?

Yes, the thickness of Acrylic Foam Tape can often be customized to meet specific requirements, depending on the manufacturer, material type, and production capabilities. Here’s a detailed breakdown of how customization works and key considerations:

1. Feasibility of Thickness Customization

Most manufacturers offer some degree of thickness flexibility, especially for industrial or bulk orders. Common scenarios include:

Adjusting standard thicknesses: For example, modifying a 2mm tape to 1.5mm or 3mm to fit precise gap requirements in machinery or construction.

Creating unique thicknesses: For specialized applications (e.g., aerospace, medical devices), tapes can be produced in non-standard thicknesses (e.g., 0.3mm for micro-bonding or 10mm+ for heavy-duty cushioning).

This is possible because foam tapes are typically manufactured by:

Cutting or slitting pre-formed foam sheets (with adhesive layers) to specific thicknesses.

Molding foam materials (e.g., EVA, polyurethane) to custom dimensions during production.

2. Limitations to Customization

Material constraints: Certain foam types have minimum or maximum thickness limits. For example, very thin tapes (≤0.2mm) may require dense, rigid foams (e.g., polyethylene) to avoid tearing, while ultra-thick tapes (≥20mm) may lose structural integrity if made from soft, low-density foams.

Adhesive compatibility: Thicker tapes often require stronger adhesives to maintain bonding strength under compression, which may restrict thickness options for tapes with lightweight or low-tack adhesives.

Order volume: Small batches (e.g., a few rolls) may not be cost-effective for customization, as setup fees for cutting/molding tools apply. Manufacturers typically require minimum order quantities (MOQs) for custom thicknesses.

3. Common Customization Processes

Slitting/skiving: Pre-manufactured foam rolls are precision-cut to reduce thickness (e.g., skiving a 5mm foam to 3mm). This is cost-effective for minor adjustments.

Custom molding: For unique thicknesses, foam is molded directly to the desired dimension before adhesive application. This is used for large or highly specific thicknesses.

Lamination: Bonding multiple thin foam layers to create a thicker tape (e.g., combining three 1mm layers to make a 3mm tape).

4. Applications for Custom Thickness Tapes

Aerospace/automotive: Tight-tolerance components where gaps between parts are non-standard (e.g., 0.8mm for engine gaskets).

Electronics: Thin tapes (0.3–0.5mm) for securing microchips or thick tapes (5–8mm) for shock absorption in rugged devices.

Construction: Tapes matching irregular wall or panel gaps (e.g., 4.5mm to seal uneven concrete joints).

In summary, thickness customization is widely available for foam tapes, with options varying by material, manufacturer, and order size. For specific needs, contacting manufacturers with details (desired thickness, material, quantity, and application) is the best way to confirm feasibility and costs.

Foam Tape Products Equipments

1. Production Capacity & Scale 24/7 operations with 500,000+ rolls/day output (standard 48mm×50y).high-volume production for industrial, masking, and double-sided tapes.

2. Core Technologies & Equipment German servo-driven extruders process BOPP/PVC/PET substrates at 150m/min.Laser-guided slitting/rewinding systems with ±0.1mm width tolerance.

3. Precision & Quality Control coating thickness accuracy ±0.002mm (Swiss precision gauges).CCD vision inspection and closed-loop tension control ensure <0.3% defect rate.

4. Automation & Smart Systems AGV robots and intelligent palletizing for end-to-end material handling.real-time MES monitoring with <0.5s anomaly response.Honeywell sensors for process optimization.

5. Sustainability & Compliance RTO emission treatment units and ISO 14001 certification.Energy-efficient,closed-loop production cycles.

Oumei Pai Decoration Materials Tape Factory

Our Team

Our Exhibition

Product Application Scope

Henan Oumei Pai Decoration Materials Co., Ltd. main products include construction site mesh cloth, industrial product tape, protective film, paper tape, anti cracking additives for construction, packaging tape, kraft paper, housing construction tape, etc. Provide OEM and ODM customization services. The products are mainly sold domestically in the major building materials and auxiliary materials markets in China, and exported to regions such as Europe, America, and the Middle East.

Foam Tape Packing and Delivery

ü Our packaging and logistics systems combine automated cartoning, robotic palletizing (1,200 rolls/minute), and smart inventory tracking to ensure rapid, error-free order processing.

ü Climate-controlled warehouses with RFID technology safeguard product quality across 50,000+ pallet spaces.

ü Partnering with global logistics leaders, we offer flexible air/sea/land freight options with 98.5% on-time delivery, enhanced by AI route optimization.

ü Sustainable FSC-certified recyclable packaging and ISO 14001-aligned processes minimize environmental impact, delivering efficiency from production to worldwide destinations.

FAQ

Q:Are you factory or trading conpany

A:We are real factory located in zhengzhou city Henan province,anytime can visit our factory

Q:What product is your factory supplying

A:All kinds of tape we can make,masking,opp,double side,fiberglass...

Q: What payment methods are accepted?

A: TT, L/C, 30%-50% deposit for initial orders.

Q: What is the lead time?

A: Standard orders: 7-15 days; expedited orders: as fast as 5 days (subject to capacity).