Product recommendation

Among the various categories of adhesive tapes, Washi Tape and Masking Tape are often confused due to the term "paper tape" in their names. However, they differ significantly in material, characteristics, and application scenarios. As a professional tape manufacturer, Henan Oumei Pai Decoration Materials Co., Ltd. will explain the differences from multiple perspectives and guide you in selecting the most suitable product based on your needs.

1. Material and Structural Differences

Washi Tape

Base Material: Made from traditional Japanese paper (washi) derived from natural plant fibers. It is soft, flexible, and easy to tear by hand.

Adhesive: Typically uses a water-based acrylic adhesive with mild stickiness, allowing for repositioning and residue-free removal.

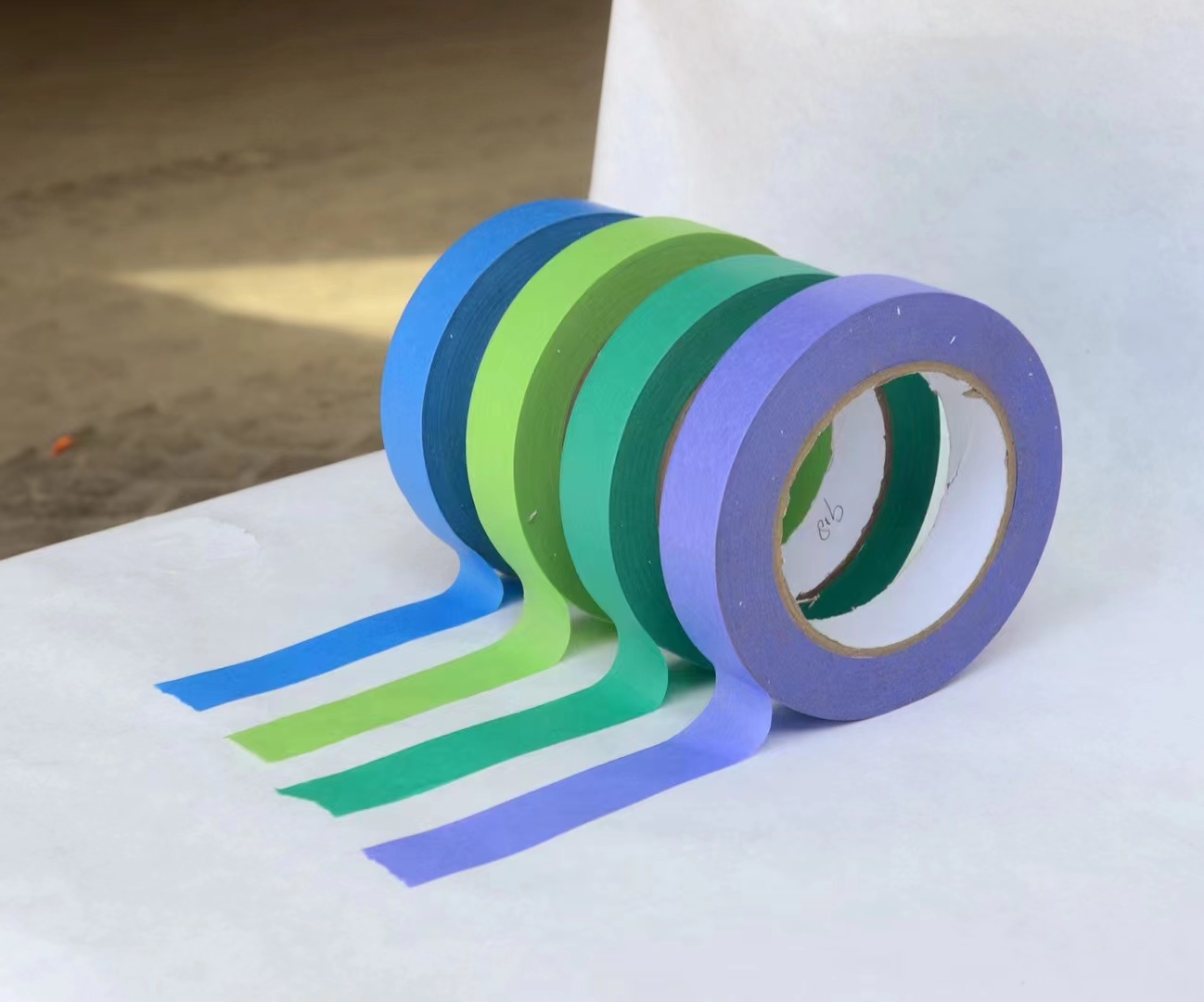

Surface Treatment: Often features intricate printed designs and vibrant colors, making it highly decorative.

Masking Tape

Base Material: Uses kraft paper or crepe paper as the base, specially treated for enhanced tensile strength and temperature resistance.

Adhesive: Commonly employs rubber-based or solvent-acrylic adhesives with adjustable stickiness (from medium to high). Some variants offer high-temperature and solvent-resistant properties.

Surface Treatment: Usually plain or single-colored, prioritizing functionality over aesthetics.

2. Key Characteristics Comparison

CharacteristicWashi TapeMasking Tape

Adhesive StrengthLow to Medium, RemovableMedium to High, Long-Lasting

Temperature ResistanceGenerally < 60°CUp to 120°C~200°C (High-Temp)

Solvent ResistanceWeakExcellent (Especially Rubber-Based)

Tear ResistanceLow, Easy to TearHigh, Difficult to Break

Primary FunctionDecoration, Crafts, Light HoldMasking, Protection, Industrial Use

3. Typical Application Scenarios

Washi Tape Applications:

Scrapbooking, Journaling, Gift Wrapping

Home Decoration, Light DIY Projects

Temporary Labeling, Office Notes

Masking Tape Applications:

Industrial Masking for Automotive, Furniture, and Metal Painting

SMT Mounting and Solder Masking in Electronics

Edge Masking and Color Separation in Construction

Temporary Fixing and Protection in High-Temperature Environments

4. Selection Guide: Match the Product to Your Needs

If You Prioritize Aesthetics and Creativity:

Choose Washi Tape for its diverse patterns and easy, residue-free removal, ideal for crafts and decoration.

If You Need High-Temperature or Solvent Resistance:

Masking Tape is the better choice, especially for industrial applications like painting and electronics.

If You Require Frequent Repositioning:

Washi Tape’s removable and residue-free properties make it suitable for temporary fixing and repeated use.

If You Need Durability and Strong Adhesion:

Masking Tape offers superior holding power and tear resistance in its high-adhesion variants.

Conclusion

Choosing the right type of tape is crucial for achieving optimal results and efficiency. As a company specializing in tape research and production, we offer a wide range of Washi Tapes and Masking Tapes to meet diverse needs, from crafting to industrial manufacturing. For more product details or customized solutions, please feel free to contact our technical support team!

Please visit product page for more information

-

- Strong Adhesive Sealing Transparent Tape Cartons Bopp Packaging tape

- Green Spray Paint Safe-Release Crepe Paper Multi-Surfaces Painters Masking Tape

- Furniture Anti Static Dust Proof Plastic Masking Protective Film

- 90m*5cm Self Adhesive Reinforced Tape Fiberglass Drywall Fiber Tape Covering Fiberglass Mesh Tape