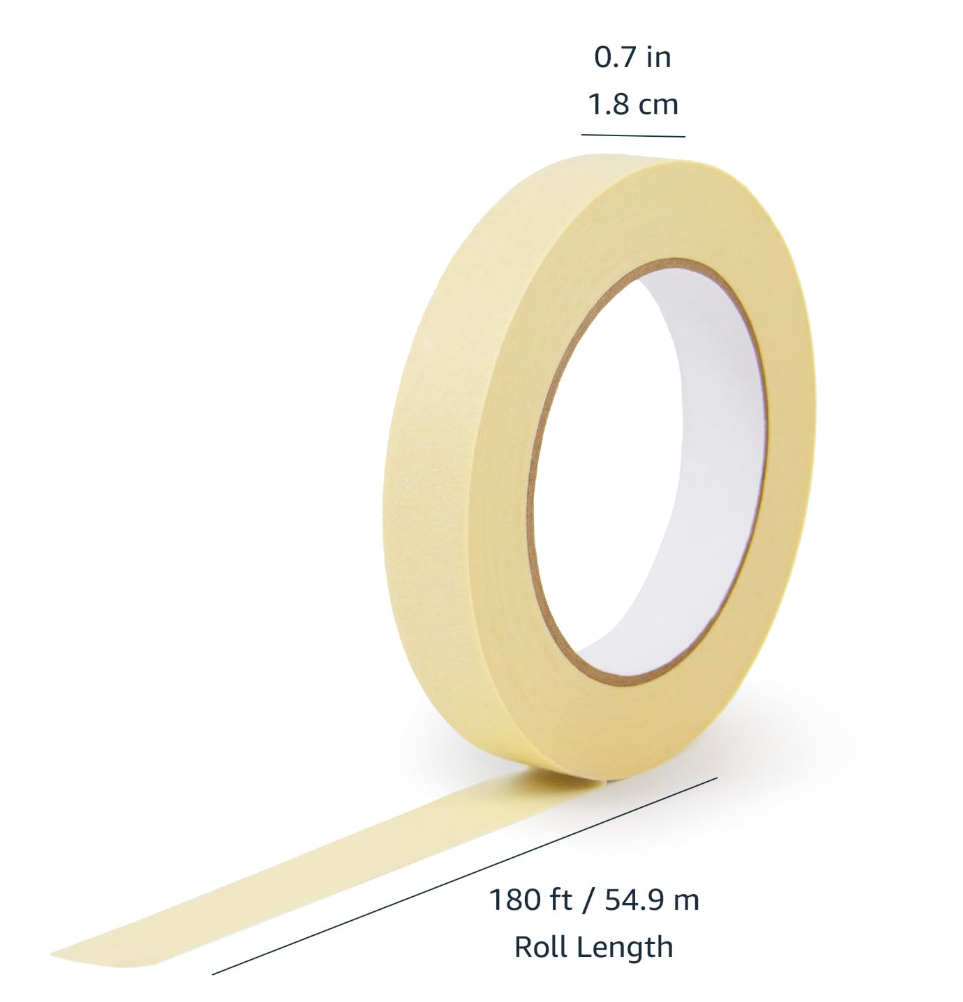

UV Resistance Windows Painting Protecting Masking Protective Tape

✅ UV Resistance Windows Painting Protecting Masking Protective Tape High adhesion yet residue-free removal for clean surfaces. ✅ UV Resistance Windows Painting Protecting Masking Protective Tape Color-coded edges enable quick width identification. ✅ UV Resistance Masking Tape Wrinkle-resistant design creates sharp paint lines.

- LOP

- CHINA

- 7-10days

- 100000pcs/days

Details

UV Resistance Windows Painting Protecting Masking Protective Tape Products Information

Masking tape is an adhesive tape made from crepe paper or composite materials, coated with pressure-sensitive glue. It features moderate adhesion, easy tear-off, and residue-free removal, often with heat or solvent resistance.

Product name: | UV Resistance Masking Tape |

Brand: | LOP |

Size: | CUSTOMIZE |

Thickness: | CUSTOMIZE |

Deliivery: | 7DAYS |

Payment: | 30%Deposit 70%Final payment |

Anti-UV High Temperature Resistant Tape Key Features

Flexible: Conforms well to curved or uneven surfaces.

Heat Resistance: Some variants withstand high temperatures (e.g., 80°C~200°C) for painting or baking.

Clean Removal: Peels off without damaging surfaces or leaving glue residue.

Color Options: Available in beige, white, blue, etc., for usage differentiation.

UV Resistance Masking Tape is widely used across industries due to its easy removal, heat resistance, and clean peel-off properties. Key applications include:

Painting & Decoration

Protecting surfaces (e.g., walls, windows) from paint overspray.

Creating sharp edges for automotive or furniture painting.

Electronics

Shielding PCB components during soldering to avoid solder splatter.

Temporarily securing wires or small parts.

Industrial Manufacturing

Marking or holding metal/plastic parts during processing.

High-temperature masking for baking processes.

Crafts & DIY

Color blocking or detail protection in art projects.

Temporary bonding for model-making or painting.

Office & General Use

Light-duty paper bonding or labeling.

Quick fixes or sealing (low-tack versions).

Specialized Uses

Construction: Covering tile joints temporarily.

Glass processing: Edge protection.

How is the Temperature Resistance of UV Resistance Masking Tape Achieved?

The temperature resistance of masking paper (typically ranging from 40°C to over 200°C) is achieved through the synergy of three core links: substrate optimization, adhesive formulation design, and process treatment. Products with different temperature resistance levels are adjusted differently for these links:

Building the Temperature-Resistant Foundation of the Substrate

The substrate of masking paper is crepe paper, and its temperature resistance depends on raw materials and processing techniques:

Raw material mixing: Ordinary masking paper mostly uses pure wood pulp, while medium and high-temperature products add synthetic fibers (such as polyester fibers, glass fibers). These fibers themselves have high heat resistance (e.g., polyester fibers can withstand temperatures above 150°C), enhancing the paper's resistance to shrinkage and embrittlement at high temperatures.

Special treatment: The substrate of some high-temperature masking papers undergoes resin impregnation (e.g., phenolic resin, epoxy resin) or silicone oil coating, forming a heat-resistant protective film on the fiber surface to reduce structural damage caused by high temperatures.

Core Guarantee of Adhesives for Temperature Resistance

Adhesives are key to determining the temperature resistance of masking paper, and their formulations are adjusted according to temperature requirements:

Room temperature type (40-80°C): Mostly use rubber-based adhesives (e.g., natural rubber, styrene-butadiene rubber), which are low-cost but have limited heat resistance.

Medium temperature type (80-120°C): Modified rubber or acrylate copolymer adhesives are used, with improved heat resistance through molecular structure optimization (e.g., increasing crosslinking density).

High temperature type (above 120°C): Silicone adhesives or high-temperature resistant resin adhesives (e.g., polyimide adhesives) are adopted. These adhesives have high molecular bond energy, are not easily decomposed at high temperatures, and are less prone to softening or glue flowing.

Synergistic Enhancement of Production Processes

Gluing process: Precise control of glue application amount and drying temperature ensures tight bonding between the adhesive and the substrate, preventing degumming at high temperatures.

Embossing treatment: Special crepe structures can reduce stress concentration at high temperatures and lower the risk of paper cracking.

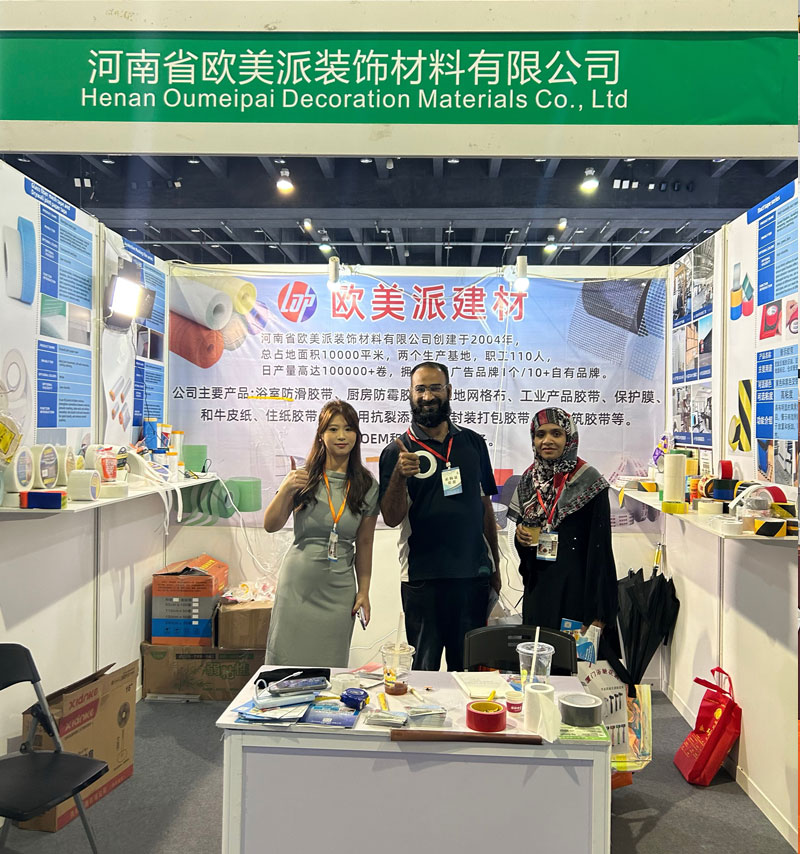

Oumei Pai Decoration Materials Tape Factory

Our Team

Our Exhibition

Product Application Scope

Henan Oumei Pai Decoration Materials Co., Ltd. main products include construction site mesh cloth, industrial product tape, protective film, paper tape, anti cracking additives for construction, packaging tape, kraft paper, housing construction tape, etc. Provide OEM and ODM customization services. The products are mainly sold domestically in the major building materials and auxiliary materials markets in China, and exported to regions such as Europe, America, and the Middle East.

UV Resistance Masking Tape Packing and Delivery

ü Our packaging and logistics systems combine automated cartoning, robotic palletizing (1,200 rolls/minute), and smart inventory tracking to ensure rapid, error-free order processing.

ü Climate-controlled warehouses with RFID technology safeguard product quality across 50,000+ pallet spaces.

ü Partnering with global logistics leaders, we offer flexible air/sea/land freight options with 98.5% on-time delivery, enhanced by AI route optimization.

ü Sustainable FSC-certified recyclable packaging and ISO 14001-aligned processes minimize environmental impact, delivering efficiency from production to worldwide destinations.

FAQ

Q:Are you factory or trading conpany

A:We are real factory located in zhengzhou city Henan province,anytime can visit our factory

Q:What product is your factory supplying

A:All kinds of tape we can make,masking,opp,double side,fiberglass...

Q: What payment methods are accepted?

A: TT, L/C, 30%-50% deposit for initial orders.

Q: What is the lead time?

A: Standard orders: 7-15 days; expedited orders: as fast as 5 days (subject to capacity).