45m*5cm Self Adhesive Reinforced Tape Fiberglass Drywall Fiber Tape Covering Fiberglass Mesh Tape

✅45m*5cm Self adhesive reinforced Drywall Covering Fiberglass Mesh Tape Exceptional durability and crack resistance across diverse surfaces. ✅45m*5cm Self adhesive reinforced Drywall Covering Fiberglass Mesh Tape High-tensile fiberglass webbing ensures structural integrity ✅45m*5cm Self adhesive reinforced Drywall Covering Fiberglass Mesh Tape Meeting international fire safety standards

- LOP

- CHINA

- 7-10days

- 100000pcs/days

Details

45m*5cm Self Adhesive Reinforced Tape Fiberglass Drywall Fiber Tape Covering Fiberglass Mesh Tape Products Information

Self Adhesive Fiberglass Mesh Tape is a versatile, durable material widely used in construction, home improvement, and industrial applications. Made from woven fiberglass threads coated with a resin (often acrylic or latex), it offers exceptional strength, flexibility, and resistance to various environmental factors. Below is a detailed breakdown of its key features, uses, and benefits:

Product name: | Self adhesive reinforced Drywall Covering Fiberglass Mesh Tape |

Brand: | LOP |

Size: | CUSTOMIZE |

Thickness: | CUSTOMIZE |

Deliivery: | 7DAYS |

Payment: | 30%Deposit 70%Final payment |

45m*5cm Self Adhesive Reinforced Tape Key Characteristics

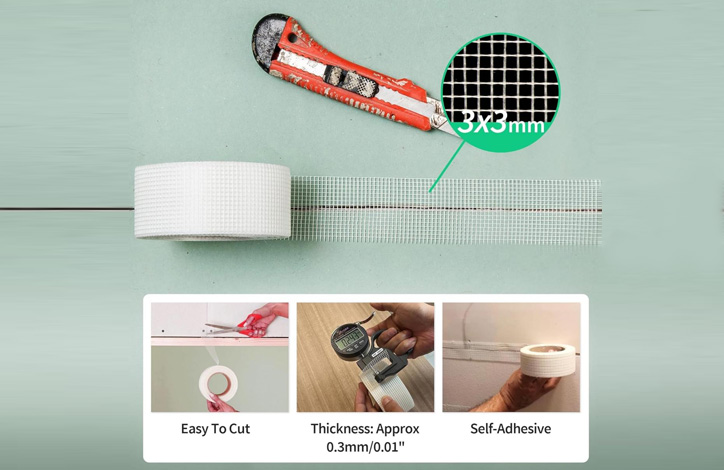

Material Composition: Woven from fine fiberglass filaments, which are then coated with a water-resistant or alkali-resistant resin to enhance durability and adhesion.

Strength & Flexibility: High tensile strength allows it to withstand stress and movement without tearing, while its flexibility enables easy application on curved or irregular surfaces.

Resistance: Alkali resistance (critical for use with cement-based materials like drywall mud), moisture resistance, and resistance to mold, mildew, and rot.

Adhesion: The resin coating ensures strong bonding with joint compounds, plaster, paint, and other finishing materials.

Primary Applications

Fiberglass mesh tape is most commonly used for reinforcing and sealing joints in construction, but its utility extends to several other areas:

Drywall Installation

The primary use: applied over seams between drywall panels to prevent cracks from forming as the wall expands or contracts. It reinforces the joint compound (mud) used to cover drywall seams, creating a smooth, durable finish.

Plaster & Stucco Work

Used to reinforce plaster or stucco coatings on walls, ceilings, or exterior surfaces. It prevents cracking in these materials, especially in high-traffic or weather-exposed areas.

Concrete Repair

Applied to small cracks or weak areas in concrete (e.g., floors, foundations) to stabilize the surface and prevent further damage. It bonds well with concrete patching compounds.

Paint & Wallpaper Preparation

Acts as a base for filling minor holes, dents, or uneven surfaces before painting or wallpapering, ensuring a uniform, long-lasting finish.

DIY & Home Repairs

Ideal for small-scale projects like repairing damaged drywall, reinforcing wood joints, or sealing gaps around windows and doors.

Advantages Over Alternatives

Compared to paper tape (a common alternative for drywall), fiberglass mesh tape offers several benefits:

Faster Application: Self-adhesive versions (backed with a pressure-sensitive adhesive) eliminate the need for pre-moistening, saving time during installation.

Reduced Cracking: Superior strength minimizes the risk of cracks forming in joints over time, even with temperature or humidity changes.

Moisture Resistance: Performs better in damp environments (e.g., bathrooms, basements) where paper tape might weaken or deteriorate.

Compatibility: Works with all types of joint compounds, including setting-type (quick-drying) mud, making it versatile for different project timelines.

Tips for Use

Surface Preparation: Ensure surfaces are clean, dry, and free of dust or debris for optimal adhesion.

Application: For drywall, apply the tape directly over the seam, press firmly to activate adhesive (if self-adhesive), then cover with joint compound, feathering the edges to blend with the wall.

Curing: Allow joint compounds or coatings to dry completely before sanding or painting to avoid damaging the tape.

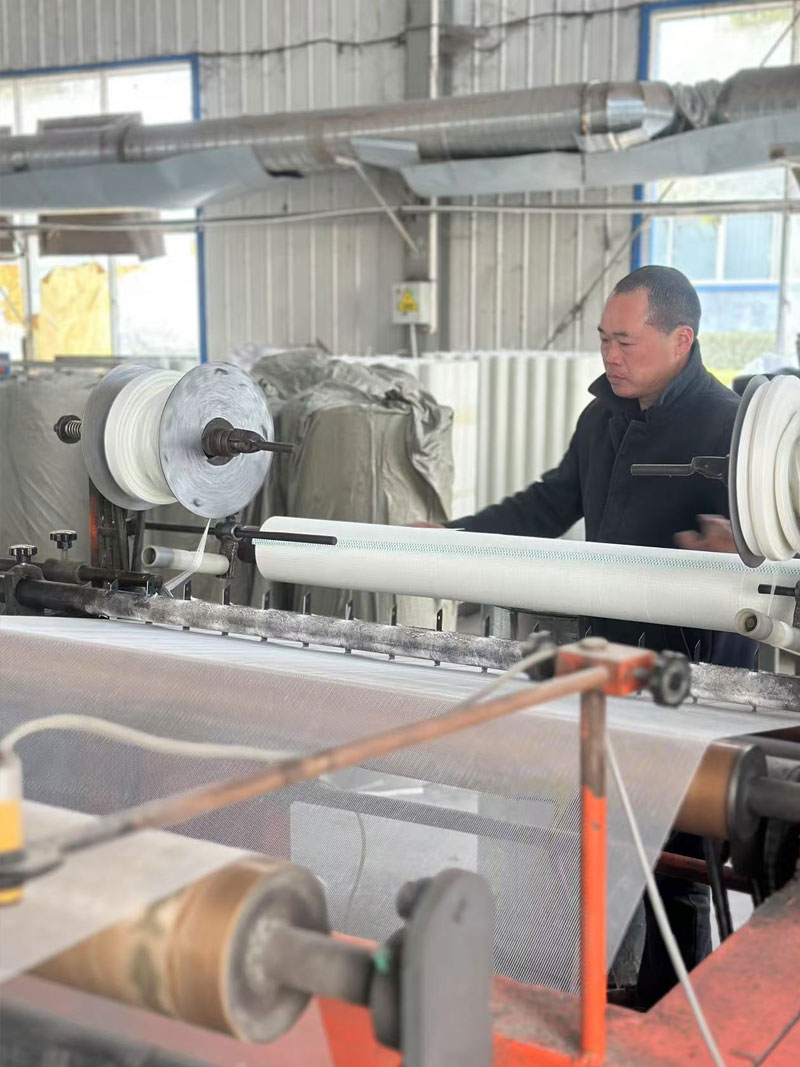

Reinforced Drywall Fiberglass Tape Products Equipments

1. Production Capacity & Scale 24/7 operations with 500,000+ rolls/day output (standard 48mm×50y).high-volume production for industrial, masking, and double-sided tapes.

2. Core Technologies & Equipment German servo-driven extruders process BOPP/PVC/PET substrates at 150m/min.Laser-guided slitting/rewinding systems with ±0.1mm width tolerance.

3. Precision & Quality Control coating thickness accuracy ±0.002mm (Swiss precision gauges).CCD vision inspection and closed-loop tension control ensure <0.3% defect rate.

4. Automation & Smart Systems AGV robots and intelligent palletizing for end-to-end material handling.real-time MES monitoring with <0.5s anomaly response.Honeywell sensors for process optimization.

5. Sustainability & Compliance RTO emission treatment units and ISO 14001 certification.Energy-efficient,closed-loop production cycles.

Oumei Pai Decoration Materials Fiberglass Mesh Factory

Our Team

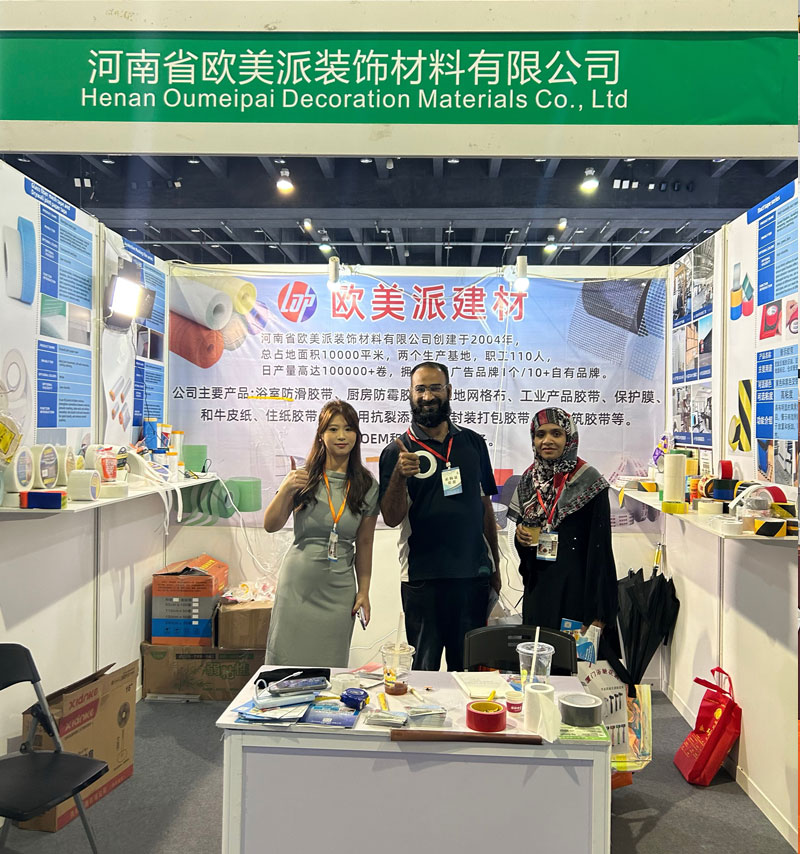

Our Exhibition

Fiberglass Mesh Tape Packing and Delivery

ü Our packaging and logistics systems combine automated cartoning, robotic palletizing (1,200 rolls/minute), and smart inventory tracking to ensure rapid, error-free order processing.

ü Climate-controlled warehouses with RFID technology safeguard product quality across 50,000+ pallet spaces.

ü Partnering with global logistics leaders, we offer flexible air/sea/land freight options with 98.5% on-time delivery, enhanced by AI route optimization.

ü Sustainable FSC-certified recyclable packaging and ISO 14001-aligned processes minimize environmental impact, delivering efficiency from production to worldwide destinations.

FAQ

Q:Are you factory or trading conpany

A:We are real factory located in zhengzhou city Henan province,anytime can visit our factory

Q:What product is your factory supplying

A:All kinds of tape we can make,masking,opp,double side,fiberglass...

Q: What payment methods are accepted?

A: TT, L/C, 30%-50% deposit for initial orders.

Q: What is the lead time?

A: Standard orders: 7-15 days; expedited orders: as fast as 5 days (subject to capacity).