Factory Tour for Our Distinguished Dubai Client

2025-08-07

Dubai Clients' Factory Visit: Successful Trial Order for Protective Materials

For global procurement teams, on-site verification is the cornerstone of building confidence in suppliers. Recently, a delegation from Dubai’s leading construction materials distributor visited our facility with targeted questions about protective materials. The visit concluded with a trial order of a 20-foot container, marking the start of a promising partnership.

Targeted Inquiries: Core Concerns for Protective Materials

Prior to the visit, the Dubai clients, specializing in construction and industrial supplies, raised critical questions specific to our product range:

"For your masking protective films, how do you ensure consistent adhesion strength across different temperature ranges (from 5°C to 45°C)?"

"In customized transparent tapes, can the adhesive layer withstand UV exposure in the Middle Eastern climate without degradation?"

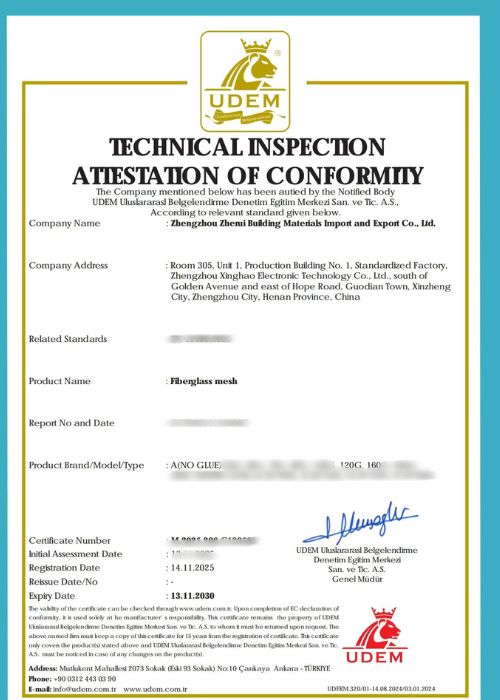

"What is the tensile strength tolerance of your fiberglass mesh cloth, and does it meet ASTM D3359 standards?"

"How quickly can you adjust production parameters for customized specifications, such as film thickness or tape width?"

These questions, rooted in real-world application scenarios, guided the focus of the on-site assessment.

On-Site Verification: Product Performance Speaks Volumes

The inspection kicked off in our R&D lab, where our materials engineer demonstrated temperature cycling tests on masking protective films. "Our films use a modified acrylic adhesive that maintains 90%+ adhesion stability between -10°C and 60°C, validated through 500+ hours of accelerated aging tests," he explained, addressing the climate resilience concern.

In the production zone, clients witnessed the precision of our customized tape line. "We can adjust coating thickness from 30μm to 150μm within 2 hours, and our UV-resistant formula retains 85% shear strength after 1,000 hours of QUV exposure," noted the production supervisor, showcasing flexibility and durability.

For fiberglass mesh cloth, the quality inspector presented test reports: "Our 80g/m² mesh achieves 1200N/50mm tensile strength, exceeding ASTM D3359 requirements by 15%, with a uniformity tolerance of ±3% across production batches."

Trial Order Confirmation: 20-Foot Container Seals the Deal

After witnessing live production runs and reviewing third-party certification documents, the client team expressed clear satisfaction. "The data-backed performance of your masking films, UV-stable tapes, and high-strength mesh aligns perfectly with our market needs in the GCC region," stated the procurement director.

The trial order, packed in a 20-foot container, includes:

10,000 rolls of blue PE masking protective film (custom 450mm width for construction site use)

5,000 rolls of transparent acrylic tape (UV-resistant grade, printed with client’s logo)

3,000 square meters of fiberglass mesh cloth (160g/m², for exterior wall insulation systems)

"This trial shipment is our first step," emphasized the client representative. "We’re particularly impressed by your ability to combine customization flexibility with strict quality control—qualities critical for long-term partnership in the protective materials sector."

Industry Impact: Setting Standards for Protective Materials Collaboration

This collaboration highlights the importance of technical transparency in industrial materials trade. By addressing region-specific challenges (such as Middle Eastern UV exposure and temperature fluctuations), we demonstrate how tailored solutions bridge global supply gaps.

We invite international buyers to explore our masking protective films, customized tapes, and fiberglass products. Whether for construction, automotive, or industrial applications, our team stands ready to deliver certified, climate-adapted solutions.